Amid global economic integration and accelerated manufacturing transformation, enterprises face intensifying market competition characterized by shortened product lifecycles, heightened customization demands, and mounting operational cost pressures. These dynamics compel organizations to pursue superior production efficiency and management capabilities. Concurrently, traditional production management methods and legacy IT systems increasingly fail to support modern business requirements despite ongoing digital transformation initiatives.

Historically, decentralized information management created operational silos across production, inventory, procurement, sales, and finance functions. Fragmented data flows, delayed information sharing, and poor cross-functional collaboration obstructed holistic resource optimization. These limitations not only drove resource waste and cost inflation but also constrained managerial effectiveness and strategic decision-making.

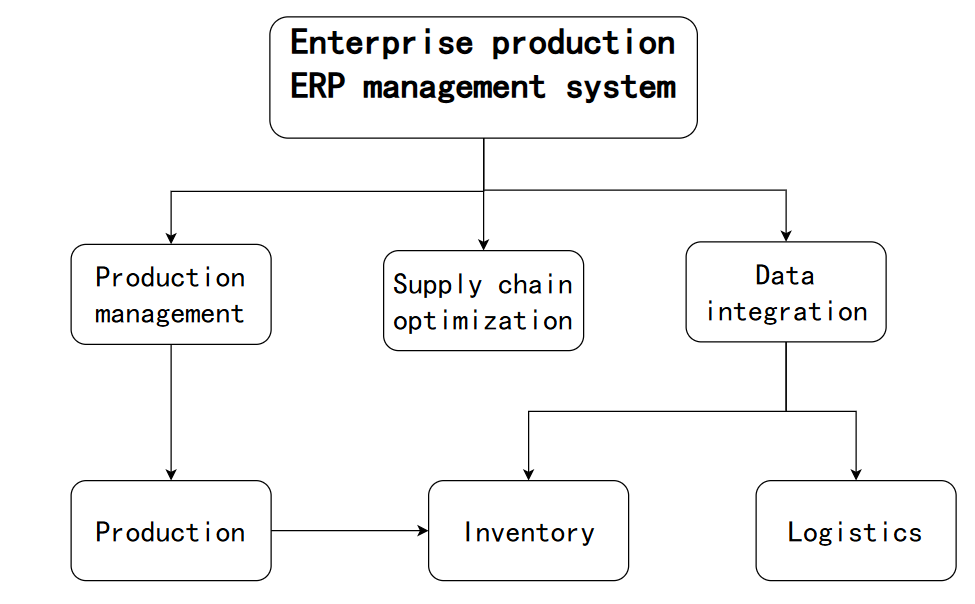

Implementing an integrated, intelligent Enterprise Resource Planning (ERP) system tailored to organizational realities has thus become imperative for achieving modernized, data-driven, and intelligent management. Such a solution must encompass production planning, supply chain management, inventory control, order processing, and data analytics—establishing a unified, efficient, visible, and controllable information platform.